Product attributes

Brand:EVERTOP

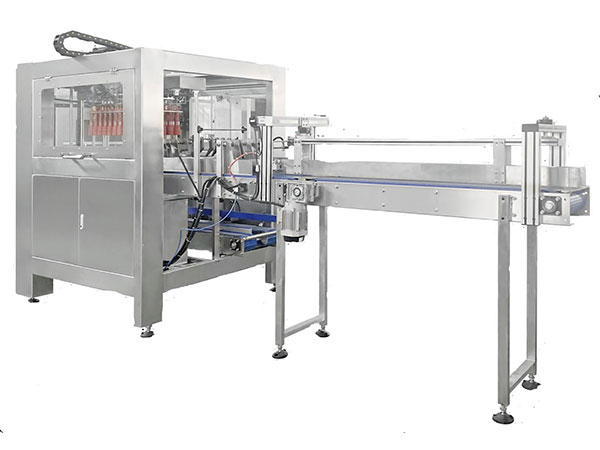

Models:ET-150

Certificate: CE

Country of origin: CHINA

Trading information

Minimum minimum order size :1 Set

Price:USD 5,000 – 100,000 per Set

Payment method:30% by T/T in advance as deposit, balance 70% by T/T or irrevocable L/C at sight before shipment

Supply capacity :20 sets per month

Delivery date :15-30 days

Conventional packaging:Wooden case

Product description

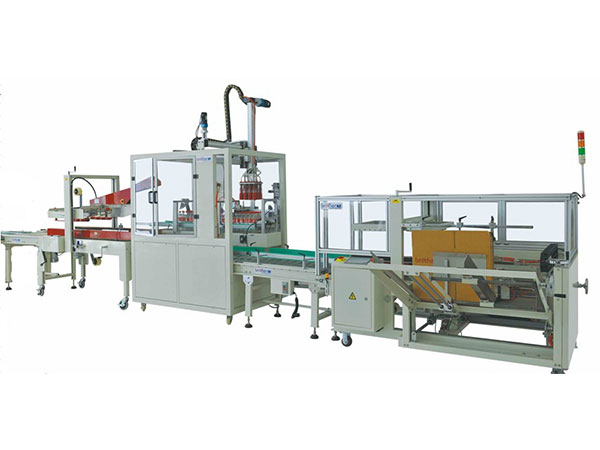

In the automatic packaging line, the case packer is the core of the operation of the entire system. The carton packing machine is used to complete the transport packaging, which is a kind of machinery that packs the finished products into cartons according to a certain arrangement. This carton packing machine produced by our company is a grabbing automatic carton packing machine, which can automatically arrange the packaging and load it into the open carton.

1.machine performance and characteristics

(1) Safety shield made of painted steel and lexan plastic, CE compliant.

(2) The mechanical parts are made of chrome-plated steel, stainless steel, and anti-corrosion aluminum.

(3) The main drive adopts adjustable speed reducer, stepless speed regulation and automatic error correction function

(4) The bottle feeding conveyor belt is composed of a polymer material chain plate with low friction coefficient, continuous bottle feeding, lane guidance, automatic speed adjustment of product position and full-line bottle feeding detection.

(5) ADK pneumatic components. Autonics photoelectric control system.

(6) The process controller based on Siemens PLC is composed of a control console and a color LCD touch screen, which provides direct modification of machine parameters;

(7) Power supply: 380V (± 10% max) 50Hz 3PH+PE, for non-380V voltage, an autotransformer can be provided.

(8) The production line is equipped with multiple fault protection and pre-alarm and fault alarm devices. All fault alarm details are highlighted on the touch screen, indicating the content that needs to be solved and the main measures. The main action actuator is equipped with electronic detection, the mechanical motion fault is equipped with a system automatic correction system, and some can also use manual operation of the reset button, the system detects and corrects itself.

2.Technical Parameters

| Model | ET-18P |

| Total power | 10KW |

| Main power | AC3-380V/50HZ |

| Compressed air pressure | 0.6Mpa |

| Compressed air consumption | 5m³/Min |

| weight | 1000KG |

| production capacity | 18 packs/minute |

3.Main configuration

| No. | Name | Brand |

| 1 | Miniature circuit breakers | Schneider |

| 2 | AC contactor | Schneider |

| 3 | Emergency stop | Schneider |

| 4 | power supply | Schneider |

| 5 | Relays | Schneider |

| 6 | PLC | Siemens |

| 7 | touch screen | Siemens |

| 8 | Frequency converters | Siemens |

| 9 | servo | Schneider |

| 10 | photoelectricity | Autonics |