Product attributes

Brand:EVERTOP

Models: ET-350

Certificate: CE

Country of origin: CHINA

Trading information

Minimum minimum order size :1 Set

Price:USD 5,000 – 100,000 per Set

Payment method:30% by T/T in advance as deposit, balance 70% by T/T or irrevocable L/C at sight before shipment

Supply capacity :20 sets per month

Delivery date :15-30 days

Conventional packaging:Wooden case

Product description

Technical Parameter

● machine size: L14000×W1250×H2100mm

● Size: machine main part: 6800×1250×2350mm, Shrink tunnel: 4200×1100×1700mm

Conveyor: 3000×1200×950mm

● max wrapping size:L420×W280×H350mm

● shrinking film material: PE

● thickness of shrinking film: 0.03-0.15mm

● thermo shrinkage tunnel max temperature: 160 – 260°can adjust

● max output per minute: 18-20 packages/min

● machine power: 42Kw

● Actual power: 30Kw/h

●Voltage requirement: 380V/50-60HZ

● Weight: 3000

● Air pressure: 0.6-0.8mpa

● Working noise: ≤65db

● Feed bottle conveyor belt width: 541mm

● Fan: 1.1Kw 3sets 380V, 60W 6sets 380V

Basic Configuration

● Nordson: glue machine

●Siemens-Germany: PLC Control system

● touch screen: Siemens 1set

● Taiwan Airtac pneumatic component 1set

●Taiwan TECO frequency 2sets

● Stainless steel wing heating tube 12pcs

● China-USA cooperation Teflon convey belt.

● Shanghai HEMEI motor and Zhenjiang Taili worm derailleur.

● South Korea Autonics photoelectricity switch, approach witch

● Thermo sealing knife aluminum casting heating board, even temperature, long usage life, our company special production.

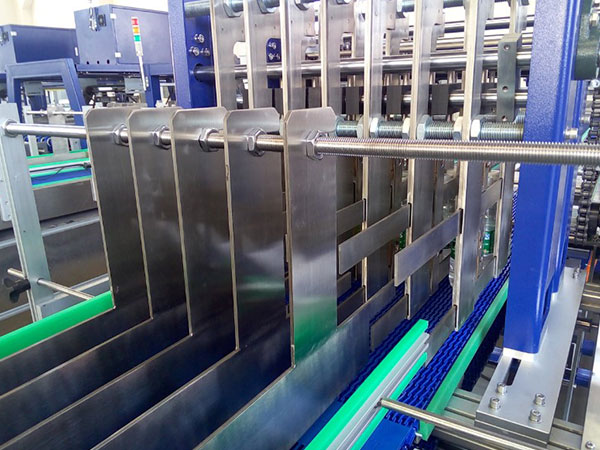

●whole machine appearance plastic spray, machine rack adopts to high-quality carbonated steel, main part adopts to stainless steel.

● Wooden case and wrapping film separate package.

Product instruction

● Frequency converter speed adjust.

● Bottle pushing, thermo sealing and cutting whole movement adopt to pneumatic fracture.

● Proximity switch control film length.

●Touch screen, PLC system greatly increase facility movement reliability.

●Three-wind recycle fan machine, ensure shrinkage tunnel inside even temperature.

● Super big wind-volume cooling system, ensure quickly get into shape.

●Anti-high temperature teflon convey belt, convey steadily, high-strength anti-abrasion.

● Frequency limitless speed adjust convey belt frame.

● convey belt height can make according client requirement, adjust range: ±100mm

● Wing stainless steel heating system, endurance

● Meet with product instant stop requirement product-bearing rack device ensure production line consistency.

Technical requirement:

1. Package type:

(1)350/500/550/600ML big bag: 4×6, 4×5; small bag: 3×4, 3×5 four type of packages.

(2)1L/1.5L/2L/2.5L big bag: 3×3, 3×4; small bag: 2×2, 2×3 four type f packages

2. Regarding can, we suggest adopt to package with tray, pack steadily.

3. Package speed: 18-20bag/min

4. Meet with pre-treatment filling speed of filling machine.

(1) 350/500/550/600ML big bag: 4×6, 4×5, (24000-29000b/h), small bag: 3×5, 3×4, (15000-18000b/h)

(2)1L/1.5L/2L big bag: 3×4, 3×3(10000-14000b/h), small bag: 2×3, 2×2 (5000-7000b/h)

5 Package material: PE thermo shrinkage film width (200-600mm), thickness(0.03-0.12mm)

The working principle of equipment

●Bottle hander film wrapping: via bottle handing pole control each group bottle movement distance, let it synchronization with film lifting pole, and let bottle push to film wrapping section belt; film lifting pole and film lifting device match torsion limit stopper, while bottle drop or bottle block, limit stopper movement let machine auto stop, after failure solve, then turn limit stopper hand wheel reset.

●Mechanism rotation: the machine rotation drove by servo motor, adopt to synchronous belt and chain rotation assembly method, ensure rotation harmony, the place that adopt to chain ration all add protection covet and lubricate device, ensure worker safe and circumstance clean.

●Have the function: while lack bottle, the machine will alarm, no bottle no film feeding function

●Controlling system: adopt to PLC and touch screen controlling, have manual. Auto move method, touch screen have full machine manipulation function, can display instant and accumulated package quantity, and enable can print with the connected printer. Setting procedure is more quickly and precisely; controlling panel adopt to electronics touch and control button controlling, can directly input and revise package type parameter, also can save different package specification parameter; timely supervise facility operation whole process. All the working procedure all have sensor checker, have ego diagnose function, if have any breakdown, facility will auto stop, alarm light blink, display breakdown type indication on the touch screen; common type reducer motor matching frequency transducer, whole machine limitless speed adjustment, move transmission is very steadily; can as above situation change, auto control machine movement speed.

●Mechanism character: mechanism spare parts adopt to stainless steel, chroming steel and strong anti-corrode character aluminum alloy etc. material; surface good quality spray printing, whole machine has strong anti-rust character.

●The facility according with safe manipulation and safe operation related criterion and standard. All the lubricate part connect central place, for convenient to handle, lubricate part all ensure have no pollute on the product.

●Performance character: high automatic degree, the machine chooses PLC programmable control, electricity part all adopt to import reliable pneumatic device and super electricity controlling technology, have steadily character, easy to handle, low failure, high automatic degree etc. advantage; easy to handle; the machine belongs to full auto production, and can limitless speed adjust and whole line synchronization operation.

Main component detail list

| NO. | Name | Specification | Number | Brand | |

| 1 | board production component | ||||

| 2 | Plant metal component | ||||

| 3 | pneumatic component | 1 | Taiwan Airtac | ||

| 4 | Electric controlling component and accessory | ||||

| Hot glue machine | 1 | Nordson | |||

| Photoelectric switch | 1 | South Korea Autonics | |||

| Proximity switch | 4 | South Korea Autonics | |||

| PLC | 1 | Siemens | |||

| Touch screen | 1 | Siemens | |||

| Frequency converter | 2 | Taiwan TECO | |||

| AC contactor | 9 | France Schneider | |||

| Mid-relay | 12 | OMRON | |||