Product attributes

Brand:EVERTOP

Models: SLM

Certificate: CE

Country of origin: CHINA

Trading information

Minimum minimum order size :1 Set

Price:USD 10,000 – 50,000 per Set

Payment method:30% by T/T in advance as deposit, balance 70% by T/T or irrevocable L/C at sight before shipment

Supply capacity :20 sets per month

Delivery date :15-30 days

Conventional packaging:Wooden case

Product description

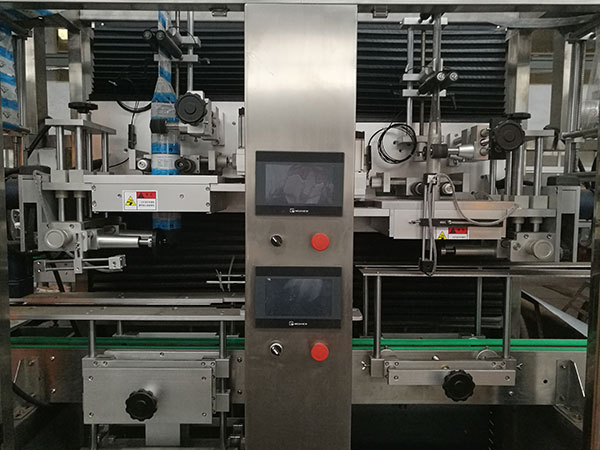

Automatic sleeve shrink PVC labeling machine applicator is popular for the bottled water and bottled drink industry because of the low cost of the label material. The labeling process consists of the label dispensing or the roll-fed sleeve label for feeding the label to the bottle mold shaft, to dispense the label by cutting it into pieces under the sensor switch control system, and servo motor control system for shooting label onto the bottles and brush the label into the refined position onto the bottle for water steam shrinking. The labeling unit is composed of three main parts: the roll-fed label dispensing unit and conveyor system, the steam shrinking tunnel, and the water steam boiler.

Working procedure of the labeling process:

1) Label setting: Roll-fed sleeve label setting by put the label onto the bottle mold in the central part of the machine, label photo sensor will be receive and give signal for the label feeding for the knife blade label cutting, and for the label shooting process by the label brushing down wheel.

2) Bottle feeding: bottle gearing worm with adjustable width to synchronize the bottle speed to be synchronized with the label part, bottle photo sensor switch will be equipped down the central bottle mold to receive the sleeve label.

3) Label dispensing: label dispensing unit will be mainly to cut the sleeve label and shoot the label onto the bottle accurately under the PLC control system, which is further driven by the servo motor system, label will be cut into pieces and shoot onto the bottle, whereas the silicone brush will be brushing the label into the right space on the bottle. The speed control will be with the synchronizing belt to be connected to each of the servo motor drive. Main mechanical parts for adjusting the width and height of the bottle are user friendly.

4) Label shrinking: Shrinking tunnel is designed with electrical hot air heating tube and the rotary system for the electrical thermal label shrinking, which is with same water steam label shrinking but with better effect.

5) International brand Panasonics PLC and servo motor system is adopted for stable operating.

Advantage

>Single positioning center guide pillar: a more stable for label delivery.

>Synchronous bottle divider: a more stable transmission for bottle.

>Bottom set of label brush: amore precision for casting label.

>Label-controlling electric-eye shelf: unique combination of tail and electric-eye to improve the precision for cutting off the membrane materials.

>Push-button control cabinet: amore humanized operation.

Independent feeding material shelf: the position of the material shelf is optional at will.

Applicable Bottle Types:

Various kinds of bottle types, for example: round bottle, square bottle, flat bottle, curved bottle and cup-shaped etc.